Crane failures cost time and money. Using the wrong wire rope can stop projects. How do you prevent this with the right ropes?

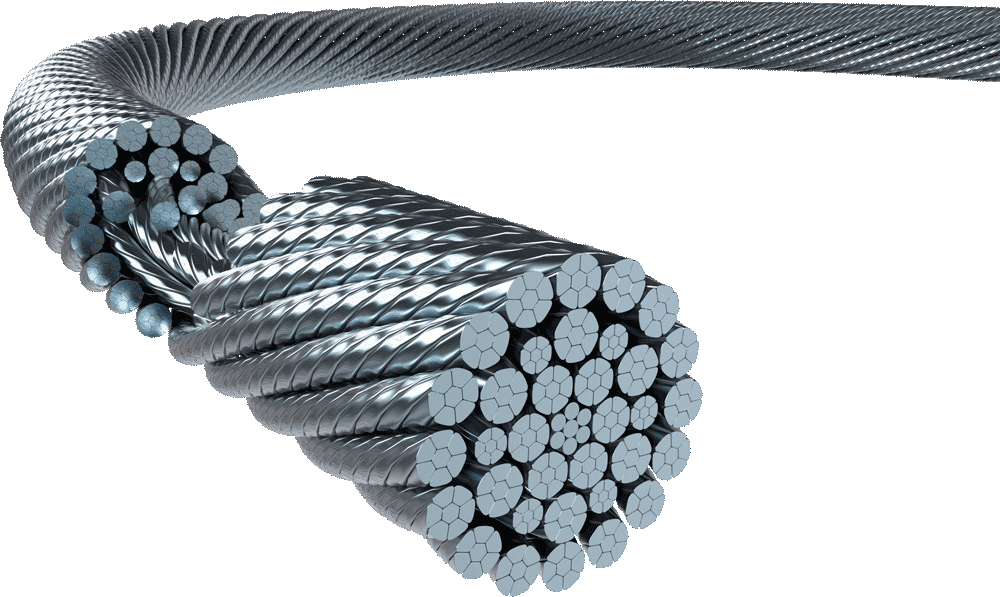

Truck-mounted crane wire ropes deliver high strength, rotation resistance, and wear durability. They make lifting safer and more efficient across construction, port, and offshore work.

I remember visiting a job site where a rope failure delayed work for days. Watching the team scramble made me realize how critical the right rope choice is. Let’s explore which ropes truly work best.

How do I choose the right truck-mounted crane wire rope?

Choosing a crane rope is not easy. Which features matter most for safe and reliable lifting?

The correct rope depends on application, rotation resistance, bend fatigue, and load capacity. Choosing wisely reduces downtime and increases safety.

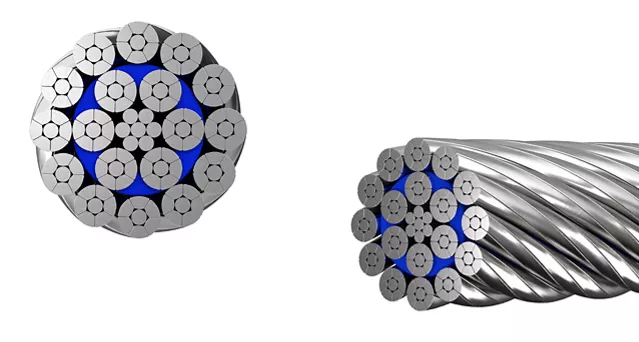

Ropes like 18XK7-EPWSC improve bend fatigue and provide robust, stable construction. They handle main and auxiliary hoist duties while maintaining high breaking strength. Smooth exteriors reduce wear on sheaves. In my experience, even small choices in rope construction impact the lifespan and safety of crane operations.

What are the applications of 18XK7-EPWSC injection molded ropes?

Where can 18XK7-EPWSC ropes make the most impact?

These ropes are ideal for main and auxiliary hoist operations, offering stability, rotation resistance, and excellent wear characteristics in heavy-duty environments.

Benefits in daily use

| Application | Advantage | Result |

|---|---|---|

| Main hoist ropes | High tensile strength | Safe lifting of heavy loads |

| Auxiliary hoist ropes | Smooth exterior | Less sheave wear |

| Construction cranes | Robust design | Reliable performance |

| Port cranes | Rotation resistant | Efficient operations |

The injection-molded, compacted design ensures the rope maintains shape under heavy loads. Operators notice reduced twisting and fewer maintenance issues. I recall a port crane operator mentioning that using 18XK7-EPWSC reduced rope replacements and improved daily workflow efficiency. Choosing this rope prevents unexpected downtime and keeps projects on schedule.

Why is 35WX7 ideal for port and construction cranes?

Do all cranes need the same rope type? Why choose 35WX7?

35WX7 is flexible and rotation-resistant, perfect for port and construction cranes. Best for single-layer drum use and heavy lifting efficiency

Performance insights

| Feature | Description | Impact |

|---|---|---|

| Rotation resistance | Maintains rope stability | Less twisting during lifts |

| Flexible construction | Easier reeving | Smooth operations |

| Single-layer drums | Optimized design | Longer rope life |

I once helped a client replace standard ropes on a construction crane with 35WX7. The difference was immediate. Lifts became smoother, fewer maintenance issues occurred, and operators reported less fatigue from handling the rope. Flexibility and rotation resistance make 35WX7 ideal for cranes with repetitive high lifts.

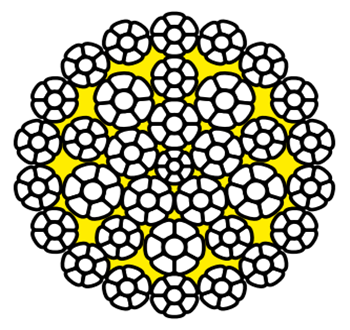

How does 35WXK7-EPWSC improve crane efficiency?

Can rope design really affect crane performance?

35WXK7-EPWSC combines rotation resistance and flexibility, improving crane efficiency on construction, port, offshore, and industrial cranes.

Why this rope stands out

| Advantage | Benefit | Application |

|---|---|---|

| Rotation resistance | Prevents twisting | Offshore cranes |

| High flexibility | Efficient reeving | Multi-part hoist systems |

| High breaking strength | Safe heavy lifting | Construction cranes |

The multistrand, compacted design minimizes internal stress and reduces wear on sheaves. Its ability to handle single or multi-part reeving systems allows operators to lift heavier loads safely. I often advise clients to consider 35WXK7-EPWSC for cranes with frequent multi-part reeving—efficiency and rope lifespan improve noticeably.

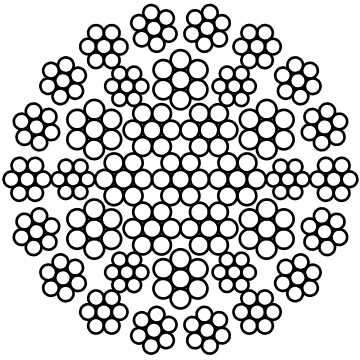

What makes multistrand non-rotating wire ropes with compacted strands crucial?

Why are compacted, non-rotating ropes preferred in high lift operations

They provide high tensile strength, abrasion resistance, and fatigue resistance. Expanded contact with bearing surfaces reduces wear on sheaves and capstans.

Performance highlights

| Feature | Description | Benefit |

|---|---|---|

| High tensile strength | Withstands heavy loads | Fewer rope failures |

| Abrasion resistance | Longer rope life | Lower maintenance cost |

| Fatigue resistance | Handles repeated lifting | Reliable daily operation |

| Compacted outer strands | More surface contact | Less sheave wear |

Ropes like 35WXK7 are excellent for ports, industrial sites, and offshore operations. Their compacted design spreads load over more strands, reducing pressure on any single wire. I often see clients using these ropes report safer lifts and longer intervals between rope replacements.

How does Aulone support clients beyond rope supply?

Is rope quality enough, or do you need support services too?

Aulone provides end fitting installation, testing, inspection, engineering, and certification, ensuring ropes meet EN12385-4 standards and project requirements

Services that matter

| Service | Benefit | Example |

|---|---|---|

| End fitting installation | Ready-to-use ropes | Main hoist rope assembly |

| Testing & inspection | Quality assurance | Verification before delivery |

| Engineering support | Customized solutions | Unique project needs |

| Certification | Compliance proof | CE, BV, RMRS, DNV, ABS |

When I first started offering Aulone ropes, I noticed clients often needed more than a rope—they wanted installation, testing, and certification. Providing these services ensures their cranes operate safely from day one. Our team also advises on rope choice for specific applications, reducing mistakes and increasing efficiency.

Which rope certifications are critical for heavy-duty crane operations?

Do certifications really matter for crane wire ropes?

Certifications like CE, BV, RMRS, DNV, and ABS confirm ropes meet strict safety standards, ensuring compliance, reliability, and peace of mind for operators.

Importance of certification

| Certification | Meaning | Why it matters |

|---|---|---|

| CE | European safety standard | Ensures legal compliance |

| BV | Bureau Veritas | Confirms quality and safety |

| RMRS | Russian Maritime | For maritime crane operations |

| DNV | Offshore safety | Certifies offshore reliability |

| ABS | American Bureau of Shipping | Ensures marine standards |

I have clients in Australia and UAE who insist on certified ropes. They understand that certification reduces liability and proves quality. Even if a rope looks identical, a certified rope guarantees tested strength and fatigue resistance.

How does rope customization enhance crane performance?

Why should operators consider customizing their wire ropes

Customizing rope length, diameter, core type, or fittings optimizes crane efficiency and matches specific project demands, improving safety and productivity.

Examples of customization

| Custom Option | Benefit | Example |

|---|---|---|

| Rope diameter | Matches load | Heavier loads require thicker ropes |

| Rope core type | Better support | IWRC vs. fiber core |

| End fittings | Faster installation | Pre-fitted sockets and thimbles |

| Coating | Reduced wear | Galvanized or plastic-impregnated |

I often see clients who customize their ropes report fewer operational issues. A rope fitted to the project’s exact needs reduces downtime and maximizes lifting efficiency.

Conclusion

Choosing the right truck-mounted crane wire rope prevents downtime, ensures safety, and improves operational efficiency. Proper selection, certification, and support make lifting projects faster, safer, and cost-effective.