Rotary drilling rigs work under extreme pressure. A wrong wire rope can break, cause accidents, and stop the whole project.

The best wire rope for Zoomlion rotary drilling rigs ensures stability, safety, and higher drilling efficiency under heavy torque and tension.

I’ve seen many projects delayed because of poor wire rope selection. This experience taught me how critical it is to choose the right one.

What makes Zoomlion rotary drilling rig wire ropes unique?

Zoomlion rigs need wire ropes that can handle constant vibration, high tension, and frequent lifting cycles.

Their wire ropes must resist rotation, corrosion, and fatigue to keep the drilling system running safely and smoothly.

The engineering behind it

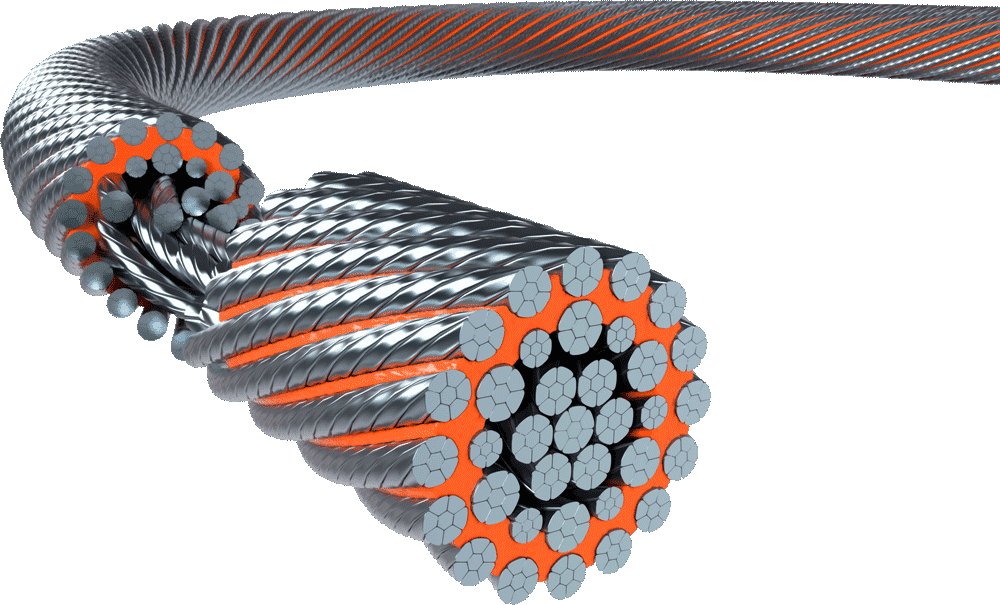

Zoomlion’s rotary drilling rigs use wire ropes like 35WXK7 non-rotating galvanized steel ropes, known for stable torque balance and longer service life. These ropes are made with compacted strands and plastic impregnation, which enhance fatigue resistance and flexibility.

| Feature | Description |

|---|---|

| Construction | 35WXK7 (non-rotating) |

| Coating | Galvanized & plastic-impregnated |

| Application | Main hoist & Kelly winch |

| Strength | High tensile, EN12385-4 compliant |

The non-rotating design helps prevent twisting during deep foundation drilling. This reduces rope wear, protects drum layers, and improves precision when drilling in hard soil conditions.

Why does galvanized coating matter for rotary drilling rig ropes?

Galvanized wire ropes can last longer, especially in wet or dusty job sites.

The zinc layer forms a protective barrier that prevents corrosion, reduces maintenance costs, and extends rope lifespan.

Comparing galvanized and bright wire ropes

| Type | Corrosion Resistance | Cost | Ideal Environment |

|---|---|---|---|

| Galvanized | Excellent | Slightly higher | Outdoor, marine, humid |

| Bright (uncoated) | Limited | Lower | Indoor, dry conditions |

For rotary drilling rigs, galvanized ropes are a practical investment. They perform better in muddy or marine projects, where water and dirt can damage bright ropes quickly.

I remember one client from Vietnam who used bright wire ropes during the rainy season. Within two months, corrosion appeared near the drum. After switching to galvanized 35WXK7 ropes, the issue disappeared completely.

How does plastic impregnation improve performance?

Plastic impregnation protects the steel core from internal wear and keeps lubricant sealed inside.

This feature helps reduce friction, noise, and heat, especially under long working hours.

Dive Deeper: The science of protection

The plastic layer acts like a shield between the strands. It prevents water from reaching the core and slows down fatigue cracking.

| Benefit | Effect |

|---|---|

| Reduced friction | Smoother winding on drums |

| Improved safety | Lower risk of internal breaks |

| Longer service life | Consistent performance over time |

For heavy-duty rigs like Zoomlion, this is essential. When drilling 60–80 meters deep, the rope must handle both vertical and torsional stress. The impregnated layer keeps the structure compact, improving stability and safety.

How does certification influence wire rope reliability?

Third-party certifications prove that a wire rope meets strict quality standards.

Certificates like BV, CE, RMRS, DNV, and ABS assure buyers that the rope passed mechanical and safety tests.

Why certifications matter in real use

Certified ropes give buyers confidence in both material strength and production consistency. For example, EN12385-4 defines tensile grade and fatigue resistance for lifting ropes.

| Certificate | Scope |

|---|---|

| BV / DNV / ABS | Marine and offshore safety |

| CE | European conformity |

| RMRS | Russian Maritime Register |

| EN12385-4 | Mechanical performance standard |

In international projects, many contractors only accept certified ropes. This ensures that their equipment passes inspection and insurance requirements.

Can wire ropes be customized for specific Zoomlion models?

Yes, customization allows better performance and compatibility with different rig models.

Buyers can select rope construction, coating, and tensile grade according to the project’s soil condition and depth.

Dive Deeper: Customization options and benefits

At Aulone, we offer custom rope diameters, lengths, and terminations such as sockets or thimbles. For example, Zoomlion SR220 rigs may use 35WXK7–Φ40mm ropes, while SR360 rigs need larger diameters for deeper foundations.

| Option | Available Choices |

|---|---|

| Diameter | 16mm–60mm |

| Surface | Galvanized / Bright |

| Core | IWRC / EPIWRC |

| Coating | Plastic impregnated |

| Marking | Custom logo & serial number |

Custom specifications help improve drum matching and reduce layer overlap. This small detail can increase rope life by up to 30%.

Why should you choose a reliable wire rope manufacturer?

A trusted manufacturer ensures stable quality and fast delivery for ongoing projects.

Factories with in-house production control can test every batch for tensile strength, elongation, and surface quality.

Inside our production at Aulone

We have four production lines with an annual capacity of 200,000 tons. Each rope goes through surface galvanizing, tension testing, and internal lubrication before packaging.

| Process | Quality Check |

|---|---|

| Drawing | Wire diameter & strength |

| Stranding | Torque balance |

| Compaction | Surface density |

| Lubrication | Uniform coating |

| Inspection | Final test with EN standard |

Our ropes are exported to Singapore, Indonesia, Vietnam, Saudi Arabia, UAE, Russia, Australia, and Canada. We support third-party inspection before shipment to ensure every client gets reliable performance on-site.

Conclusion

The right wire rope makes drilling safer, faster, and more efficient.