Lifting heavy loads high into the air? Worried about the load spinning dangerously out of control? This is a common and serious problem in many lifting operations.

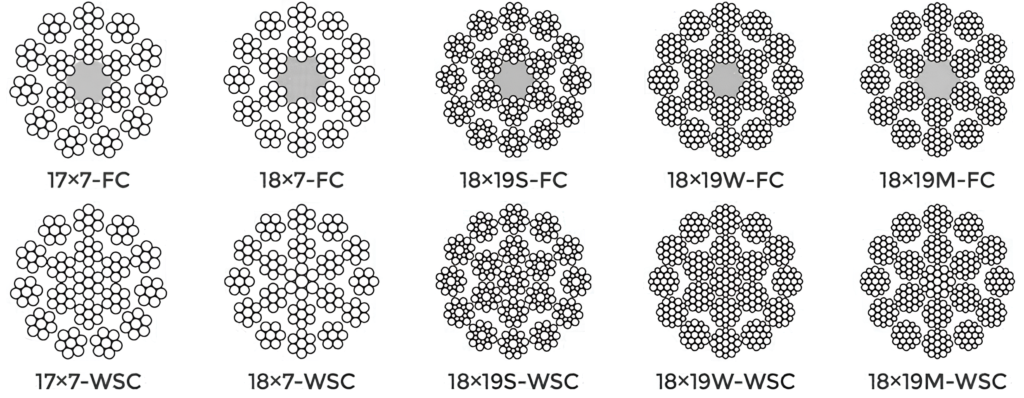

Class 19×7 wire rope is the standard because its unique construction counteracts the natural tendency of a rope to spin under load. Its inner and outer strands are laid in opposite directions, creating a torque-balanced design ideal for single-line hoisting.

I once visited a site where a critical, expensive component was damaged during a lift. The cause was simple: the wrong rope was used, and it spun uncontrollably. This is why understanding the design of a 19×7 rope isn’t just academic; it’s essential for safety and efficiency.

How Does the 19×7 Construction Actually Prevent Spinning?

You might look at a wire rope and just see a bundle of steel. But the way those wires and strands are assembled is a clever piece of engineering designed for a specific job.

A 19×7 rope has an independent wire rope core made of 7 strands, which is laid in one direction. The 12 outer strands are then laid around this core in the opposite direction. These opposing forces cancel each other out, neutralizing the rope’s urge to spin.

The Role of the Inner Core

Think of the inner core as the foundation. It’s a complete, smaller wire rope on its own (often a 6×7 construction with a fiber or steel core). When a load is applied, this inner rope wants to twist, or un-lay, in a specific direction. For example, if it’s a right-hand lay rope, it will want to twist to the left under tension. This is the initial rotational force that needs to be controlled. In our factory, we pay close attention to the tension and lay angle of this core, as its consistency is the first step to a stable final product.

The Counter-Action of the Outer Strands

This is where the magic happens. The outer layer, consisting of 12 strands, is laid in the opposite direction to the inner core. So, if the inner core is right-hand lay, the outer strands are left-hand lay. When the same load is applied, these outer strands want to twist in the opposite direction (to the right, in our example). Because the force exerted by the outer strands is designed to be equal and opposite to the force from the inner core, the two twisting tendencies effectively cancel each other out. The result is a rope that remains remarkably stable, with minimal rotation even at great heights.

Why This Matters in Practice

A standard rope, like a 6×25 class, has all its strands laid in the same direction. It’s strong, but under load, all the strands try to unwind together, causing significant and often dangerous spinning of the attached load. This is especially problematic in what we call single-part reeving, where only one line is supporting the hook.

Here is a simple comparison to illustrate the difference:

| Feature | Standard 6×25 Wire Rope | Rotation Resistant 19×7 Wire Rope |

|---|---|---|

| Construction | All strands laid in the same direction. | Inner core and outer strands laid in opposite directions. |

| Behavior Under Load | High tendency to spin or unwind. | Very low tendency to spin. It remains stable. |

| Ideal Use Case | Multi-part reeving systems where two or more lines prevent block rotation. | Single-line hoisting (e.g., main hoist line on a mobile crane). |

This balanced design is why 19×7 is classified as a rotation-resistant, not non-rotating, rope. There will always be a small amount of rotation as the rope settles under load, but it’s a fraction of what a standard rope would experience.

When Should You Choose 19×7 Over Other Wire Ropes?

Choosing the right wire rope is not just about lifting capacity; it’s about matching the rope’s design to the application. Using the wrong rope can lead to poor performance and serious safety risks.

You should choose a Class 19×7 wire rope for single-part hoisting applications, especially with high lifting heights. This is common for the main hoist lines on mobile cranes, tower cranes, and some overhead cranes where a free-hanging load must not rotate.

Ideal Applications for 19×7 Ropes

I work with many crane rental companies and construction project managers. Their primary concern is lifting materials safely and precisely, often to great heights.

- Mobile and Crawler Cranes: The main hoist line on these cranes is almost always a single line. A 19×7 rope ensures that loads like steel beams or precast concrete panels can be lifted and placed without spinning.

- Tower Cranes: On high-rise construction sites, the lift height can be enormous. Any rotation at the hook is magnified and can make it impossible for workers to handle the load safely. 19×7 is the go-to choice here.

- Foundation and Piling Rigs: These machines often use a single line for lifting piling tools and cages. Stability is key to positioning these components correctly.

When NOT to Use 19×7 Ropes

It’s equally important to know when a 19×7 rope is the wrong choice. A common mistake I see is using a rotation-resistant rope where it’s not needed, or where it can actually be detrimental.

- Multi-Part Reeving Systems: If your crane uses two, four, or more parts of the line to support the hook block, the reeving itself mechanically prevents the block from twisting. A standard, more flexible rope like a 6×36 class is often a better and more durable choice here.

- Applications with Swivels: Never, ever attach a free-spinning swivel to a rotation-resistant rope. The rope’s stability comes from the opposing forces of its inner and outer strands. A swivel allows the rope to unwind, which can cause the outer strands to loosen and the inner core to tighten, leading to a catastrophic failure known as “cabling” or “bird-caging.”

Application Suitability Checklist

To make it simple, here is a quick guide. Before you order, think about your specific application.

| Application Type | Use 19×7? | Why or Why Not? |

|---|---|---|

| Main Hoist on Mobile Crane | Yes | Single-line lift where load stability is critical. |

| Boom Hoist Line | No | This is a structural rope, not a hoisting one. Rotation is not the main concern; fatigue resistance and strength are. |

| Overhead Crane (Single Line) | Yes | If the hoist uses a single line and the lift height is significant. |

| Overhead Crane (Multi-part Reeve) | No | The reeving provides stability. A more flexible rope is better suited. |

| Lifting with a Tagline | Maybe | A tagline can control rotation, but 19×7 provides an extra layer of safety, especially if the tagline fails. |

What are the Key Specifications to Check for 19×7 Ropes?

When a purchasing manager sends me an inquiry, they often list a size and a length. But to provide the right rope, we need to look closer at the specifications. Getting these details right is the key to performance and safety.

The most critical specifications are the rope’s nominal diameter, minimum breaking force (MBF), tensile strength of wires, and its compliance with international standards like EN12385-4. You also need to confirm the lay direction and lubrication type.

Understanding Minimum Breaking Force (MBF)

This is perhaps the most important safety metric. The MBF is not an average strength; it is the absolute minimum load that a new rope is guaranteed to hold before breaking when tested according to standards. Never confuse this with the Safe Working Load (SWL) or Working Load Limit (WLL), which is the MBF divided by a safety factor (typically 5:1 for hoisting). When we produce a rope, we perform destructive tests on samples from each batch in our own laboratory to ensure it meets or exceeds the stated MBF.

The Importance of EN12385-4 Compliance

A specification sheet might say a rope is “19×7,” but that doesn’t tell you about its quality. Compliance with a recognized standard like EN12385-4 (for cranes) is your assurance of quality. This standard dictates:

- Tolerances for diameter.

- Minimum breaking force calculations.

- Material requirements for the steel wires.

- Testing procedures.

When we provide a certificate for our ropes, like one from BV, DNV, or ABS, it independently verifies that our product meets these strict international requirements. This is non-negotiable for my clients in sectors like marine and offshore.

Critical 19×7 Rope Specifications Explained

Let’s break down a typical spec sheet. These are the values you need to match to your equipment and your lift plan.

| Specification | What It Means for You and Your Operation |

|---|---|

| Nominal Diameter (e.g., 20mm) | This must match the groove size of your crane’s sheaves and drum. A mismatched size leads to rapid rope wear and damage. |

| Minimum Breaking Force (e.g., 324 kN) | This is the ultimate strength of the rope. It is used to calculate the Safe Working Load (SWL). Higher is not always better if it means sacrificing flexibility. |

| Wire Tensile Strength (e.g., 1960 N/mm²) | This indicates the strength of the individual wires used to make the rope. Higher grades like 1960 or 2160 provide a better MBF for a given diameter. |

| Lay Type (e.g., Right Hand Ordinary Lay) | This determines how the rope should be spooled onto the drum to prevent induced twist. Most cranes specify a certain lay. |

| Core Type (IWRC) | For 19×7 ropes, this is always an Independent Wire Rope Core (IWRC), which provides strength and support to the outer strands. |

| Certification (e.g., EN12385-4) | This is your proof that the rope was manufactured to a recognized safety and quality standard. |

Can 19×7 Wire Ropes Be Galvanized or Plastic Impregnated?

A standard steel rope is vulnerable to its environment. Rust, dirt, and internal friction are its enemies. Thankfully, we can protect a 19×7 rope to extend its life and improve its performance in harsh conditions.

Absolutely. A 19×7 rope can be galvanized to protect against rust in marine or wet environments. It can also be plastic-impregnated, a process that locks in lubricant and seals the rope from dirt, drastically improving its fatigue life.

The Galvanization Process

Galvanization is the process of applying a protective zinc coating to the steel wires before they are stranded into a rope. I often recommend this to my clients in Singapore, Indonesia, and other coastal regions. The zinc acts as a sacrificial layer; it corrodes before the steel does, effectively preventing rust. This is essential for any application exposed to rain, humidity, or saltwater. While it adds a small cost, it pays for itself by significantly extending the rope’s service life.

The Advantage of Plastic Impregnation (PI)

This is a more advanced form of protection. During manufacturing, a special polymer is extruded onto the rope, filling all the internal spaces between the strands. This does two amazing things:

- It locks in the factory lubricant permanently. This ensures the rope’s core and strands can move smoothly against each other, which reduces internal friction and wear, the main cause of rope fatigue.

- It creates a barrier against the outside world. Dirt, sand, coal dust, and moisture cannot get inside the rope to grind away at it from the inside out.

I have supplied plastic-impregnated ropes to mining companies in Australia, and they see a much longer service life compared to standard ropes operating in the same dusty, abrasive conditions.

Choosing Between Ungalvanized, Galvanized, and PI

The choice depends entirely on your operating environment and budget. There’s no point in paying for protection you don’t need, but skipping it when you do need it is a costly mistake.

| Rope Finish | Best For… | Key Benefit | Consideration |

|---|---|---|---|

| Ungalvanized (Bright) | Dry, clean, indoor, or temperate environments. | Lowest initial cost. | Will rust quickly if exposed to moisture. Requires regular lubrication. |

| Galvanized | Outdoor use, marine, high humidity, and coastal areas. | Excellent corrosion resistance. | Slightly higher cost than ungalvanized. |

| Plastic Impregnated (PI) | Abrasive and dirty environments (e.g., mining, heavy construction) or where lubrication is difficult. | Maximum fatigue life and protection from contamination. | Highest initial cost, but often the lowest total cost of ownership in harsh conditions. |

What Are the Common Mistakes to Avoid When Handling 19×7 Ropes?

Even the highest quality rope from our factory can be damaged by improper handling, installation, or maintenance. Over the years, I’ve seen a few simple, avoidable mistakes cause big problems for our clients.

The most common mistakes are using a swivel, installing the rope improperly which induces twist, using sheaves with worn or incorrect groove sizes, and shock-loading the rope. These actions can permanently damage the rope’s structure.

The Critical Don’t: Using Swivels

This is the number one rule for rotation-resistant ropes. I cannot stress this enough. A swivel allows the rope to do exactly what it was designed not to do: rotate. When it rotates freely, the outer strands can un-lay and become loose, while the inner core tightens. This will cause a “birdcage” deformity, where the outer strands bulge out from the rope. A bird-caged rope has lost its structural integrity and must be removed from service immediately.

Correct Installation and Breaking-In

How you transfer the rope from the delivery reel to your crane’s drum is critical. The reels must be properly aligned and a small amount of back-tension applied to the delivery reel to ensure the rope spools tightly and evenly. Unspooling a rope by dropping the reel on its side and pulling the rope off will induce a huge amount of twist and ruin it before its first lift.

After installation, it’s good practice to run the rope through a few lifting cycles with a light to moderate load. This allows the strands to settle into their final working positions, a process known as breaking-in.

Inspection: Your First Line of Defense

Regular inspection is not just a regulatory requirement; it’s your best tool for catching damage before it leads to failure.

Here is a simplified checklist of what to look for when inspecting a 19×7 rope:

| Sign of Damage | What It Means | Action to Take |

|---|---|---|

| Broken Wires | This is a normal sign of fatigue over time. | Count the number of broken wires in one rope lay. Compare this to the retirement criteria in your manual or relevant standard (e.g., ISO 4309). |

| “Bird-caging” | The rope has been subjected to torsional imbalance, often from a swivel or improper installation. | Retire the rope immediately. The rope’s structure is compromised. |

| Kinking or Crushing | The rope has been bent around a sharp corner or crushed on the drum. | Retire the rope immediately. The steel wires are permanently bent and weakened. |

| Reduction in Diameter | This often indicates a failure of the inner core. | Measure the rope diameter carefully. If it is significantly less than the nominal diameter, retire the rope immediately. |

| Heavy Corrosion | The rope has been exposed to moisture without adequate protection or lubrication. | Assess the severity. Surface rust can be managed, but deep pitting that causes wires to become stiff requires retirement. |

Conclusion

Class 19×7 rope is the industry’s choice for safe, single-line lifting because of its stable, rotation-resistant design. Choosing the right specifications and handling it correctly ensures maximum safety and value.