I often see crane teams struggle with rope failures. It brings delays and risks. I want to share how the right truck crane wire rope solves these problems.

Truck crane wire rope is important because it carries the full lifting load, controls stability, reduces rotation, and protects the crane from unsafe stress during lifting.

I learned this lesson early in my work when a small rope mistake caused a big delay. It pushed me to study wire rope deeply so I can choose better ropes today.

What makes a good hoist rope for a truck crane?

I look at hoist ropes first because they take the highest stress in every lift.

A good hoist rope has high tensile strength, strong rotation resistance, stable structure, and consistent quality that matches EN12385-4 and real crane working conditions.

Key performance factors I always check

I check the rope from structure to coating.

I test rotation resistance, load balance, and breaking force.

I confirm the stability of every layer.

I also consider hot-dip galvanized or plastic-coated options for extra corrosion protection.

Performance Table I Use When Selecting Hoist Ropes

| Factor | Why It Matters | What I Look For |

|---|---|---|

| Tensile strength | Handles heavy loads | Grade 1770 / 1960 |

| Breaking load | Safety margin | Higher than crane rated load |

| Rotation resistance | Keeps hook stable | Multi-layer compacted design |

| Surface coating | Rust and wear control | Hot-dip galvanized or plastic-coated |

| Certification | Compliance and trust | EN12385-4, CE, BV, ABS |

Why hoist ropes fail in real projects

I saw failures caused by bending fatigue, overload, bad lubrication, and mismatch between rope structure and drum groove.

I now talk with clients early to avoid these mistakes.

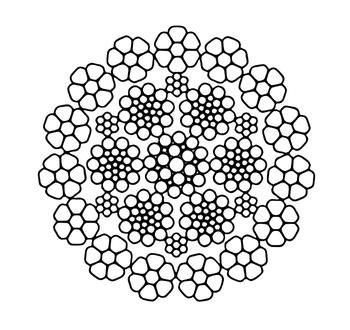

How does the 35WXK7 hoist rope help with rotation resistance?

I use 35WXK7 when clients need better stability in long boom lifting.

35WXK7 reduces hook rotation because its inner and outer layers twist in opposite directions, balancing torque and keeping the load stable during lifting.

Why I like working with 35WXK7

The rope keeps the hook steady in wind.

It handles shock loads well.

It works well on multi-layer drums.

It is available in hot-dip galvanized or plastic-impregnated options for longer life.

Structural Table

| Feature | 35WXK7 |

|---|---|

| Type | Non-rotating |

| Layers | Multi-layer compacted |

| Strength | High tensile strength |

| Surface | Galvanized or plastic-impregnated |

| Best Use | Main hoist of truck cranes |

Typical lifting cases

I have seen this rope used in boom lengths over 40–60 meters.

It helps when the crane lifts fragile or long materials that must stay in one position.

Why do some crane teams choose 15XK7 for lighter lifting tasks?

I pick 15XK7 when clients want a simple and cost-effective rope.

15XK7 offers moderate rotation control and good flexibility, making it suitable for general lifting where the load is lighter but still needs stable movement.

Where 15XK7 fits well

I use it for truck cranes with frequent short lifts.

It works well in rental fleets that change job sites often.

It fits drums with small bending diameters.

Hot-dip galvanized 15XK7 is excellent for outdoor or humid environments.

Comparison Table

| Feature | 15XK7 | 35WXK7 |

|---|---|---|

| Rotation control | Medium | High |

| Flexibility | High | Medium |

| Surface coating | Galvanized optional | Galvanized or plastic-impregnated |

| Best for | General hoist | Long boom hoist |

| Cost | Lower | Higher |

What I learned using this rope

It performs well if the operator avoids sudden shock loads.

It lasts longer with regular lubrication.

Galvanized 15XK7 is a great balance of cost and corrosion resistance.

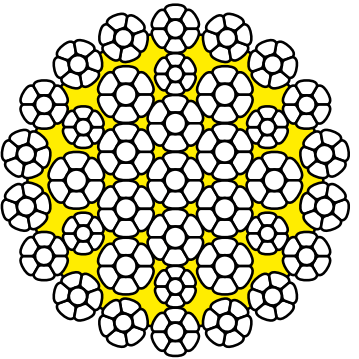

Why is 35WXK7-EPWSC useful for high-demand truck crane lifting?

I use 35WXK7-EPWSC when a project needs both strength and protection.

35WXK7-EPWSC has a plastic-impregnated core that blocks water, reduces internal wear, and keeps the rope stable in harsh lifting environments. Hot-dip galvanized coating adds extra corrosion resistance.

How the EPWSC layer helps

The plastic layer keeps wires supported.

It reduces strand movement.

It protects from corrosion in marine or rainy sites.

The galvanized layer protects the outer wires from rust in wet environments.

Technical Table

| Specification | Detail |

|---|---|

| Structure | 35WXK7-EPWSC |

| Core | Plastic impregnated |

| Coating | Galvanized optional |

| Best Use | Coastal lifting, heavy duty hoist |

My experience in harsh environments

I used this rope in coastal regions with salt moisture.

It reduced internal rust and gave longer service life.

It also lowered the sound during lifting.

Which rope should I choose for my truck crane hoist?

I answer this question often when clients compare different working sites.

Choose 15XK7 for general lifts, 35WXK7 for long boom and stable hoisting, and 35WXK7-EPWSC for harsh or high-corrosion environments. Hot-dip galvanized ropes work well outdoors.

Quick selection guide

| Working Condition | Best Rope | Reason |

|---|---|---|

| Short lifts, general load | 15XK7 | Flexible and cost-effective |

| Long boom, rotation control | 35WXK7 | Strong anti-rotation |

| Marine or wet sites | 35WXK7-EPWSC | Anti-corrosion protection |

| Heavy duty lifting | 35WXK7 | High strength |

| Outdoor projects | Any rope | Hot-dip galvanized for rust prevention |

| Multi-layer winding | 35WXK7-EPWSC | Stable structure |

How I match ropes with cranes

I check drum groove, sheave size, load chart, and lifting angle.

I match rope strength with crane rating to keep a safe margin.

I also choose galvanized options if the project will be outdoors or in humid conditions.

Conclusion

High-quality and galvanized hoist ropes keep every truck crane lift safe and steady.