Are you worried about project delays from rope failure? A snapped rope can cause huge equipment damage and safety risks. 6×19 galvanized wire rope provides a strong and versatile answer.

You should choose 6×19 galvanized wire rope because it offers a great balance of flexibility and abrasion resistance. Its zinc coating provides excellent corrosion protection, making it a durable choice for many industrial jobs.

I once helped a client whose rope was wearing out too quickly on their crane. We switched to a 6×19 rope. The difference in service life was huge. Let’s explore what makes this rope so effective.

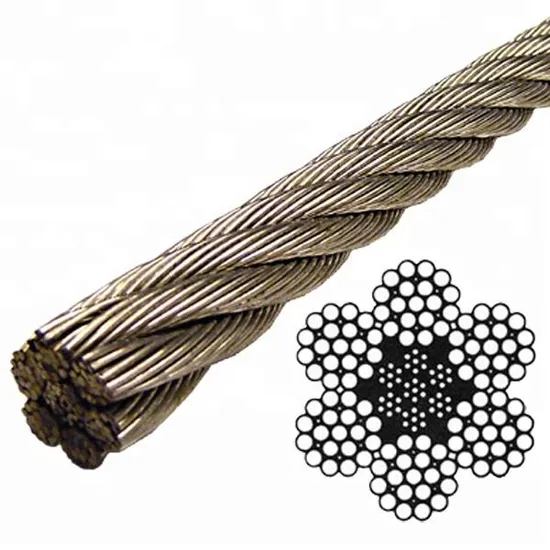

What Does the 6×19 Classification Actually Mean?

The numbers “6×19” look technical. But they are simple. They tell you exactly how the rope is built. Let’s break it down into simple parts.

The 6×19 classification means the wire rope is made of 6 main strands that are twisted together. Each of those strands is formed by a group of 16 to 26 individual wires. This design provides a good mix of flexibility and wear resistance.

To really understand this, we need to look at the rope’s construction from the inside out. A wire rope is not just one thick piece of metal. It is a machine with many moving parts.

Understanding the “6” – The Strands

The first number, “6,” is the number of strands in the rope. Imagine six smaller ropes. Now, imagine twisting those six ropes together around a central core. That is the basic structure of a 6×19 wire rope. These strands are what give the rope its main body and strength.

Understanding the “19” – The Wires Per Strand

The second number, “19,” is a category. It means each of the six strands is made from a class of 16 to 26 individual wires. It is rarely exactly 19 wires. This is a common point of confusion for buyers. The term “19 Class” includes several common constructions.

Let’s look at the most common types you will find in this class.

| Construction | Description | Best For |

|---|---|---|

| 6×19 Seale | Has larger outer wires. This makes it very resistant to abrasion and crushing. | Hoisting applications where the rope runs over sheaves and drums. |

| 6×25 Filler Wire | Has smaller wires filling the gaps between larger wires. This improves flexibility and fatigue resistance. | A good general-purpose choice. Often used in cranes and winches. |

| 6×26 Warrington Seale | A combination design. It offers a good balance of abrasion resistance and fatigue resistance. | Very common for a wide range of industrial and oil and gas jobs. |

The key takeaway is that the 6×19 class is not one single type of rope. It’s a family of ropes. They all share the same basic design of 6 strands. But the arrangement of wires inside those strands changes their performance. This allows you to pick a rope that is just right for your machine.

How Does Galvanization Protect the Wire Rope?

Steel wire rope’s biggest enemy is rust, or corrosion. Galvanization is its best shield. It’s a simple process with a powerful result that protects your investment.

Galvanization protects the rope by coating the steel wires with a layer of zinc. This zinc layer acts as a sacrificial barrier. It corrodes first, which stops the steel underneath from rusting. This greatly extends the rope’s life.

This protection is not just a simple coating like paint. It is an electrochemical process. This is what makes it so effective, especially in harsh environments.

The Sacrificial Anode Principle

Steel is mostly iron. Zinc is a more active metal than iron. When both metals are present in a corrosive environment (like salt water or humid air), the zinc will corrode first. It sacrifices itself to protect the steel. This is why you see galvanization used on everything from ships to guardrails. Even after the zinc coating gets scratched, the zinc nearby continues to protect the exposed steel.

As a manufacturer, we see the difference clearly. I once inspected two ropes used in a marine environment near Indonesia. One was ungalvanized (bright) and the other was galvanized. After just one year, the bright rope showed significant rust. The galvanized rope looked almost new.

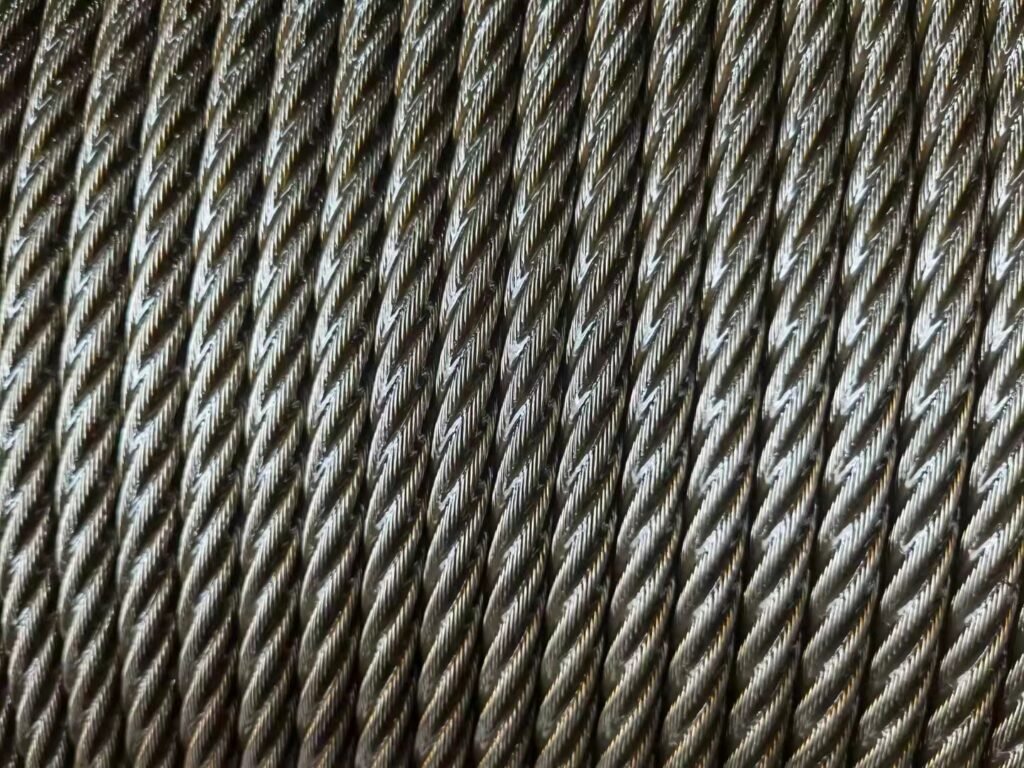

Hot-Dip Galvanization Process

The most common method is hot-dip galvanization. The individual steel wires are thoroughly cleaned. Then, they are passed through a bath of molten zinc. This creates a strong, bonded layer of zinc on the wire’s surface. We perform this step before the wires are spun into strands. This ensures every single wire has full protection, both inside and outside the rope.

Here is a simple comparison.

| Feature | Bright (Ungalvanized) Rope | Galvanized Rope |

|---|---|---|

| Corrosion Resistance | Poor. Prone to rust quickly in humid or wet conditions. | Excellent. The zinc layer provides long-lasting protection. |

| Initial Cost | Lower. | Slightly higher due to the extra galvanizing process. |

| Long-Term Value | Lower. Needs more frequent replacement in many environments. | Higher. Lasts much longer, reducing downtime and replacement costs. |

| Common Use | Indoor environments, or where lubrication is excellent. | Outdoor, marine, and humid environments. |

| Appearance | Shiny and metallic, turns dull or rusty over time. | Dull grey or bright silver, depending on the finish. |

For customers in places like Singapore or the UAE, where humidity and salt are a factor, I almost always recommend galvanized rope. The small extra cost upfront saves a lot of money and trouble later.

What are the Most Common Applications for 6×19 Wire Rope?

This rope is a true workhorse in many industries. You can see it almost everywhere if you know what to look for. Its versatility is its greatest strength.

The most common applications include general hoisting, crane lines, winches, and rigging slings. Its balance of properties also makes it suitable for boom pendants, guy wires, and some types of overhead cranes where abrasion is a concern.

The reason it is so popular is its “middle-of-the-road” design. It is not the most flexible rope. It is not the most abrasion-resistant rope. But it does both jobs very well. This makes it a reliable and cost-effective choice for many machines.

Let’s look at specific examples in different industries.

Construction and Cranes

In construction, reliability is everything. The 6×19 class is a favorite for mobile cranes and smaller tower cranes. I’ve supplied ropes for major building projects in Australia where our 6×19 galvanized ropes were used for almost every lifting task.

- Main hoist lines on mobile and crawler cranes.

- Winch lines on excavators and dozers.

- Temporary guy wires for support structures.

Marine and Shipping

The marine environment is very tough on steel. The combination of 6×19 construction and galvanization is essential here. We export many ropes to port authorities in Vietnam and Russia for these very purposes.

- Mooring lines for securing vessels.

- Towing lines for tugboats.

- Hoisting ropes on ship cranes and dockside cranes.

- Winch ropes for anchor handling.

General Industrial and Mining

In factories, warehouses, and mines, you need ropes that can handle daily wear and tear. The 6×19 class provides the durability needed for these repetitive tasks.

- Overhead crane ropes for moving materials.

- Winch ropes for pulling heavy loads.

- Drilling lines on some types of smaller drilling rigs.

- Shaft hoist ropes in some mining applications.

The key is to match the rope to the equipment. If your machine’s manual specifies 6×19 class rope, it is because the designers found it offers the best service life for that specific application.

What Key Specifications Should You Check Before Buying?

Buying wire rope is not just about its diameter. You need to check several key details to ensure safety and performance. Getting the wrong specs can be a costly mistake.

You must check the diameter, construction (e.g., 6×25), core type (FC or IWRC), and lay direction (e.g., right regular lay). Also, confirm its tensile strength grade and that it meets relevant standards like EN 12385-4.

I always walk my new clients through a checklist. It helps them order the exact rope they need and avoid confusion. Let’s create a checklist you can use.

Critical Specification Checklist

This table breaks down the essential information you need to provide and confirm when you place an order.

| Specification | What to Look For | Why It’s Important |

|---|---|---|

| Diameter | The nominal diameter in millimeters (mm) or inches (in). | Must match the sheave and drum grooves on your equipment. An incorrect size causes rapid wear. |

| Construction | The strand and wire configuration, such as 6×19 Seale or 6×25 Filler Wire. | Determines the rope’s flexibility and resistance to abrasion. |

| Core | FC (Fiber Core) or IWRC (Independent Wire Rope Core). | FC provides more flexibility. IWRC provides more strength and crush resistance. |

| Tensile Strength | The grade of the steel, e.g., 1770 N/mm² or 1960 N/mm². | Determines the rope’s Minimum Breaking Load. Higher grade means stronger rope. |

| Finish | Ungalvanized (Bright) or Galvanized. | Galvanized is for corrosion protection in outdoor or marine environments. |

| Lay Direction | The direction the strands are twisted. Most common is Right Regular Lay (RRL). | Must be correct for the drum winding. Using the wrong lay can damage the rope. |

| Standards | Compliance with international standards, like EN 12385-4 or API 9A. | Ensures the rope was manufactured and tested to strict quality and safety rules. |

Also, always ask about certifications. For serious industrial use, you should request a factory test certificate for every rope. If you operate in specific regions or industries, you might also need third-party certificates from bodies like ABS, DNV, or Lloyd's. We provide these for clients who need them. It is an important part of guaranteeing quality.

How Do You Select the Right Core for Your 6×19 Rope?

The core is the heart of the wire rope. It supports the outer strands. Choosing between a fiber core and a steel core is a critical decision. It directly impacts the rope’s performance.

Select a Fiber Core (FC) for applications needing more flexibility and where a lower breaking load is acceptable. Choose an Independent Wire Rope Core (IWRC) for higher strength, better crush resistance, and lower stretch, especially on multi-layer drums.

Both cores have their place. The choice depends entirely on your application. Let’s look at the advantages and disadvantages of each.

Fiber Core (FC)

A fiber core is typically made from natural fibers like sisal or synthetic materials like polypropylene. This core is saturated with lubricant. As the rope bends and stretches, the core releases this lubricant, which helps to reduce internal friction and corrosion.

- Advantages: More flexible, easier to handle, and can absorb some shock loads.

- Disadvantages: Can be crushed under high pressure, has a lower breaking strength than a steel core rope of the same size, and can rot or degrade in certain conditions if it’s a natural fiber.

Independent Wire Rope Core (IWRC)

An IWRC is a small wire rope that serves as the center of the larger rope. It is essentially a rope within a rope. This makes the entire structure more solid.

- Advantages: Increases the breaking strength by about 7.5%. Provides excellent resistance to crushing on drums. Has less stretch than a fiber core rope. It is also more resistant to heat.

- Disadvantages: Less flexible than a fiber core rope.

Here is a side-by-side comparison to help you decide.

| Feature | Fiber Core (FC) | Independent Wire Rope Core (IWRC) |

|---|---|---|

| Strength | Lower | Higher (approx. 7.5% more) |

| Flexibility | Higher | Lower |

| Crush Resistance | Poor | Excellent |

| Stretch | Higher | Lower |

| Heat Resistance | Poor | Good |

| Typical Use | Lifts that don’t spool on multiple layers, slings | Crane hoist ropes, multi-layer spooling, high-load situations |

For a purchasing manager at a crane company, this choice is very important. For a main hoist line that spools onto a drum many layers deep, an IWRC is almost always the right choice. It prevents the lower layers from being crushed. For a simple sling that needs to be flexible, an FC might be better.

Conclusion

The 6×19 galvanized rope is a reliable choice. Its balanced design and rust protection make it ideal for many jobs. Always check your specifications to ensure safety and performance.