Maintenance and Care for Rotary Drilling Rig Wire Ropes: Ensuring Longevity and Safety

Wire ropes are critical components in rotary drilling rigs, responsible for lifting, hoisting, and supporting heavy loads.

Rotary Drilling Rig Maintenance and Care: Ensuring Optimal Performance and Longevity

Rotary drilling rigs are essential for foundation work, oil and gas drilling, and various other heavy-duty applications

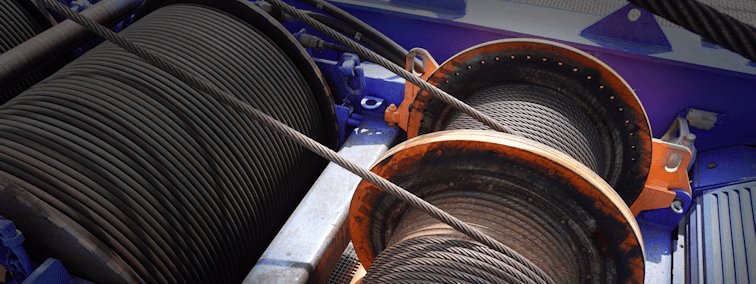

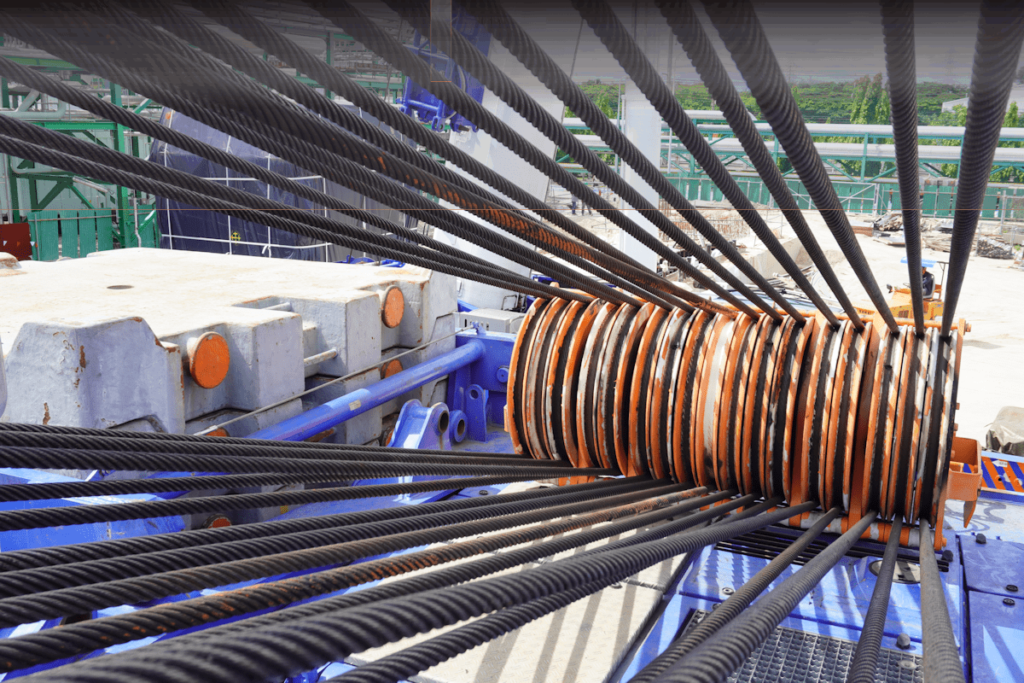

Introduction to Rotary Drilling Rig Wire Ropes

Wire ropes are integral to the performance and safety of rotary drilling rigs, which are essential in industries such as construction, mining, and energy.

Selecting the Right Steel Wire Rope

Steel wire ropes are indispensable components across various industries, from construction and mining to elevators, bridges, and marine applications

How to stop corrosion in a steel cable?

Steel cables are widely used in applications requiring high strength and flexibility, including marine operations, mining, construction, and transportation.

How to increase the life of a crane wire rope?

Crane wire ropes are essential components of lifting machinery, providing the tensile strength and flexibility necessary for a wide range of industrial applications.

Advantages of Steel Wire Ropes?

Evolution and Historical Significance

Origins: Detailed history of steel wire ropes starting from Wilhelm Albert’s early designs in mining, highlighting why steel quickly became the material of choice.

What is the best way to store a wire rope sling?

Proper storage of wire rope slings is essential for preserving their structural integrity, preventing premature wear, and ensuring they remain ready for safe and efficient use

Will galvanized wire rope rust?

Yes, galvanized wire rope can eventually rust, though it is highly resistant to corrosion compared to uncoated steel wire rope

What are the additional applications of galvanized steel wire?

Galvanized steel wire is versatile due to its enhanced durability and resistance to corrosion.

Does length of rope changes with weather?

Yes, the length of a rope can indeed change with weather conditions due to variations in temperature and humidity.

What is the difference between steel and metal wire?

The terms “steel wire” and “metal wire” refer to different types of materials, and the distinction between them lies primarily in the type of material used and their specific properties.